To reduce the challenges faced by governments and hospital managements in providing oxygen facilities for patients, a 10-member team of students and research staff members of IIT Bombay’s Tata Centre for Technology and Design, Department of Chemical Engineering, and Nex Robotics, a start-up by the alumni of the institute, have designed ‘reBreather’, a semi-closed circular breathing system that would allow patients to breathe in unused exhaled oxygen which has been filtered to remove carbon dioxide.

Looking at the shortage of medical-grade oxygen supply and high demands across India, the team decided to work on this design to bring out possible solutions.

It primarily focuses on reducing oxygen wastage and enhancing the lifetime of oxygen cylinders for COVID19 patients.

While it has not been clinically tested or approved for routine use on COVID19 patients, the team has released the ‘do-it-yourself manual’ design in the public domain to encourage further research and testing. “The main objective is to provide solutions to the patients needing emergency oxygen,” said Amaldev V, Senior Project Manager, Tata Centre for Technology and Design, IIT Bombay. He advised that the device be used under the observation of medical professionals and doctors. “We have designed just a basic structure and modification can be done as per individual/group of experts using their expertise. We have put up all the information of the prototype in the public domain, and are asking experts to help us with by adding more innovative idea and modifying the design, which can further be executed and make a fully approved working model,” he added.

Using exhaled oxygen

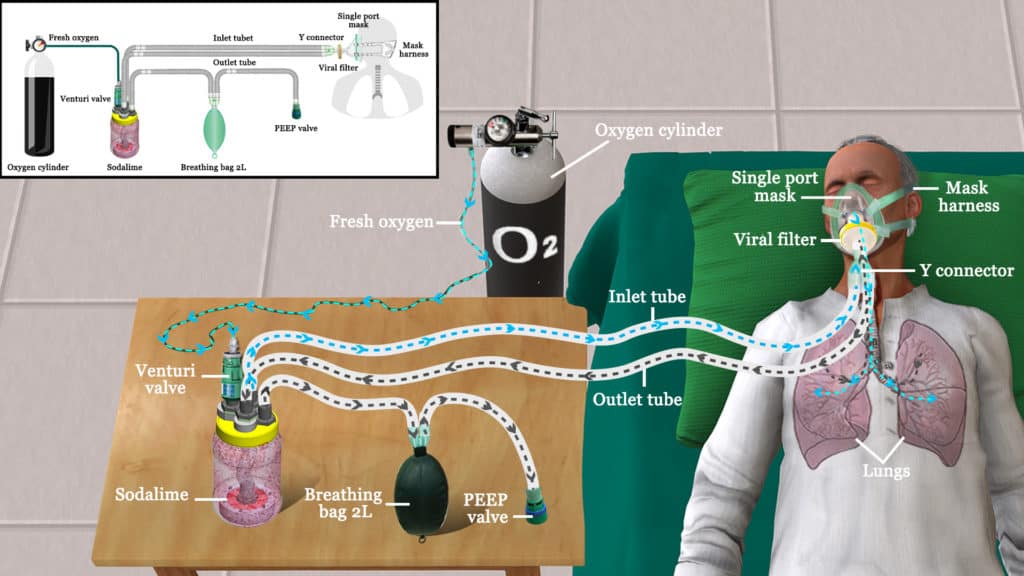

The reBreather is an innovative way to reuse the exhaled oxygen. It is a portable device and easy to assemble which facilitates recirculation of exhaled breath by scrubbing out carbon dioxide (CO2) and blending in fresh oxygen (O2) to maintain a clinically desired fraction of inspired oxygen (FiO2) level.

“The prototype has been tested on healthy human volunteers and is found to be effective in its design and function. The approvals for clinical trials take time because of which we have made our designed prototype available to the public,” said Prof. Santosh Noronha, professor-in-charge for the entire project and head of Tata Centre for Technology and Design, IIT Bombay.

During the making of the design, doctors from Mumbai who have been working on COVID-19 patients were consulted by the team to get help for the technical detailing.

The reBreather has been designed using the technical concept of breathing devices used during mountaineering and underwater sea diving. But those breathing devices have a significantly more complex designs. In reBreather, the team has designed a fully closed loop system with air sensors measuring concentrations of carbon dioxide and adjusting the input oxygen flow. A single unit cost around Rs. 50,000.

Read more: Vaccines are almost here. Time for a large-scale testing system, says a Mumbai team

How it works

Explaining the working of the device, the researchers explained that the reBreather has an inlet section which pumps in fresh oxygen from an oxygen cylinder or a centralised oxygen system. The oxygen flow rate is set on the cylinder with a flow meter. An adjustable venturi valve is given at the input to allow for external air to be automatically pulled in based on the desired oxygen flow rate. A one-port mask is attached to the patient. The exhaled air is fed to a container that has medical-grade soda lime. This soda-lime selectively absorbs carbon dioxide from the exhaled output and allows the rest of the air to pass through to the inlet section of the system. The soda-lime changes color once it has exhausted its capacity to absorb carbon dioxide and can be replaced.

As per the calculations published by the team, the recirculation of oxygen can reduce the number of oxygen cylinders required for a critical COVID-19 patient from nine to almost one per day.

A healthy person normally breathes in 5 liters (L/min) of air per minute of which about one L/min is oxygen being inhaled; of this, 250 milliliters (mL/min) of oxygen is consumed, and the rest 750 mL/min is exhaled unused.

Critically ill Covid-19 patients can receive up to 50 L/min of oxygen using a high-flow nasal cannula and mask combination. Consequently, during one open-loop breathing cycle for such patients, most of the oxygen is lost back to the atmosphere.

Ready for mass production?

While the details of reBreather were published under Creative Commons on May 15, the team has been getting responses from the medical professionals, doctors, and organisations. “Few doctors have responded by writing back to us after seeing the prototype design. The main issue is about scaling up mass production. Certain parts of the designed device, are not possible to be purchased off-the-shelf, so we need to redesign and minimize the parts of valves used in the device. More such suggestions and opinions have been mailed to us by the experts in the healthcare field after reading about it,” added Amaldev V.

Amaldev further added, “We are working on modifying the designs further so that the soda lime can also be regenerated and reused. We are also looking at exploring different chemical options which maybe can alter soda lime. We are working on further modifications to make the designs better and easier to mass manufacture. We will keep updating the hardware design folder with modified design variations.”

The details of the prototype and the design assets are available in the public domain here.

Nitrogen plant to oxygen plant

Last month, other researchers from the institute worked on a solution to convert the nitrogen generator to an oxygen generator.

Another team from IIT Bombay demonstrates this conversion as a fast solution for the current oxygen crisis in India.

At IIT Bombay, a PSA (Pressure Swing Adsorption) Nitrogen plant in the Refrigeration and Cryogenics Laboratory was identified for conversion to validate the proof of concept. Prof. Milind Atrey, Dean (R&D), who also specializes in Cryogenic Engineering along with Tata Consulting Engineers Limited (TCE), took up a pilot project to evaluate the conversion of PSA Nitrogen Unit to PSA oxygen unit by fine-tuning the existing Nitrogen Plant setup, which is usually available in Industrial plants across India.

This setup for the experiment was developed within three days, and the initial tests have shown promising results. Oxygen production could be achieved at 3.5 atmospheres (atm) pressure with a purity level of 93-96 %. This gaseous oxygen can be utilized for COVID19-related needs across existing hospitals and upcoming COVID19-specific facilities by providing a continuous supply of oxygen.